Building Information Modeling in Structures

The Benefits of Using BIM in Structural Framing

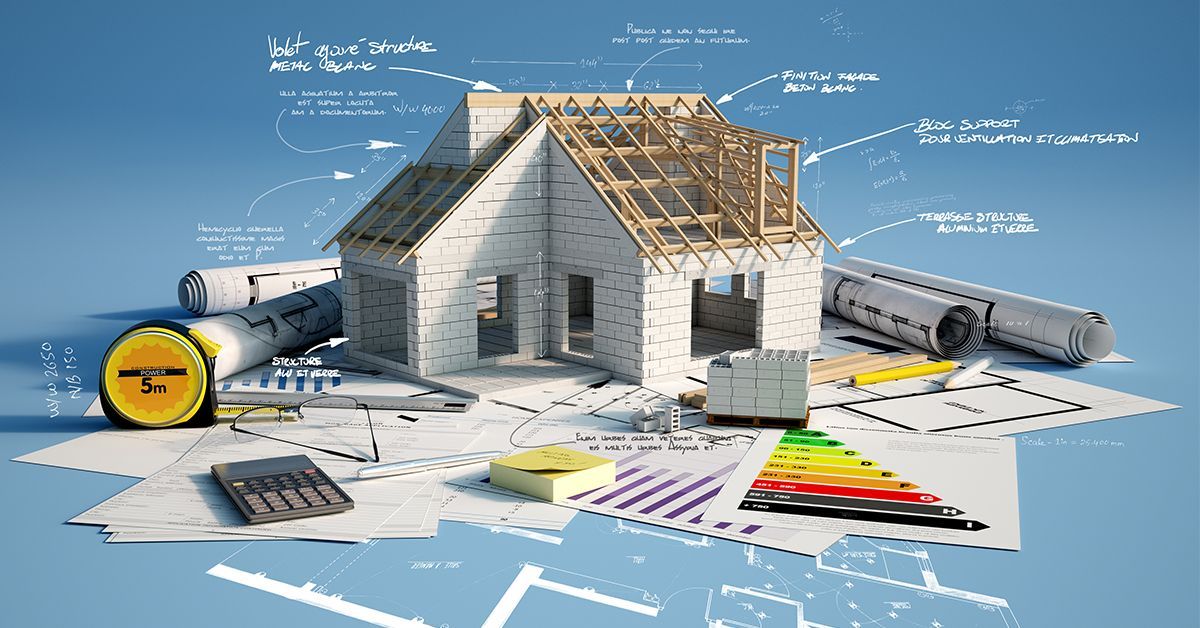

Building Information Modeling (BIM) offers numerous benefits when it comes to enhancing structural framing in the construction industry. One of the primary advantages is the ability to create intelligent 3D models that provide a comprehensive view of a building's structural elements. These models allow architects, engineers, and construction professionals to visualize the project in its entirety, enabling a more accurate and efficient design process.

With BIM, stakeholders can easily identify clashes or issues before construction begins. This early detection allows for adjustments to be made, preventing costly rework and delays. BIM also facilitates better coordination between various trades involved in the construction process, minimizing conflicts and ensuring smooth collaboration.

Another significant benefit of BIM in structural framing is the ability to optimize material usage. By accurately modeling and simulating the structure, architects and engineers can make informed decisions about the most efficient use of materials, reducing waste and costs. Additionally, BIM allows for precise quantity takeoffs, simplifying the estimation process and enabling more accurate cost projections.

Furthermore, BIM enhances communication and collaboration among project stakeholders. By providing a centralized platform, BIM enables real-time access to project information, fostering better coordination and reducing the likelihood of misunderstandings. This collaborative approach improves decision-making processes and enhances overall project efficiency.

In summary, the benefits of using BIM in structural framing are vast. From improved visualization and clash detection to optimized material usage and enhanced collaboration, BIM is transforming the construction industry by streamlining processes and improving project outcomes.

Case Studies Showcasing Successful Implementation of BIM in Structural Framing Projects

Real-world case studies provide valuable insights into the successful implementation of BIM in structural framing projects. Let's explore a few examples that highlight the power of this technology in driving efficiency and improving project outcomes.

Case Study 1: Burj Khalifa, Dubai

The Burj Khalifa in Dubai, the tallest structure in the world, stands as a testament to the power of BIM. The complex structural framing of this iconic building required meticulous planning and coordination. BIM played a crucial role in facilitating the design process, enabling the architects and engineers to visualize the intricate structural elements and identify potential clashes.

By utilizing BIM, the project team was able to optimize the framing design, reducing material waste and costs. The 3D modeling capabilities of BIM allowed for accurate quantity takeoffs, ensuring precise estimation and cost projections. The collaborative nature of BIM also fostered effective communication between the project stakeholders, resulting in a seamless construction process.

Case Study 2: London Crossrail Project, UK

The London Crossrail project, one of the largest infrastructure projects in Europe, relied heavily on BIM for its structural framing requirements. With numerous underground tunnels and stations, the complex nature of the project demanded precise coordination and collaboration. BIM proved instrumental in achieving these objectives.

By utilizing BIM, the project team was able to create detailed 3D models of the underground structures, allowing for accurate clash detection and resolution. The digital nature of BIM enabled effective collaboration between the various trades involved, resulting in improved coordination and reduced conflicts. The project's success is a testament to the power of BIM in enhancing structural framing in large-scale infrastructure projects.

Case Study 3: One World Trade Center, New York

The construction of One World Trade Center in New York showcased the immense benefits of BIM in structural framing. The complex design and tight deadlines required a highly efficient and collaborative approach. BIM provided the necessary tools to achieve these objectives.

By utilizing BIM, the project team was able to visualize the entire structure in 3D, identifying potential clashes and design issues before construction began. The accurate quantity takeoffs facilitated by BIM allowed for precise estimation and cost control. The collaborative platform of BIM improved communication and coordination among the project stakeholders, resulting in a successful and timely completion of the project.

These case studies demonstrate the transformative power of BIM in enhancing structural framing. From iconic skyscrapers to large-scale infrastructure projects, BIM has proven to be a game-changer in the construction industry, driving efficiency, collaboration, and improved project outcomes.

Key Features and Functionalities of BIM Software for Structural Framing

BIM software for structural framing offers a wide range of features and functionalities that enable architects, engineers, and construction professionals to enhance their projects. Let's explore some of the key features and functionalities of BIM software specifically tailored for structural framing.

3D Modeling and Visualization

One of the primary features of BIM software is its ability to create intelligent 3D models of a building's structural elements. This feature allows professionals to visualize the project in its entirety, providing a comprehensive view of the framing design. The 3D modeling capabilities facilitate better decision-making and enable accurate clash detection, ensuring a more efficient and error-free construction process.

Clash Detection and Resolution

BIM software excels in clash detection and resolution, a crucial aspect of structural framing. By analyzing the 3D models created, the software can identify clashes or conflicts between different structural elements or trades. This early detection enables stakeholders to make the necessary adjustments and resolve conflicts before construction begins, saving time and avoiding costly rework.

Material Optimization

Another key functionality of BIM software is its ability to optimize material usage. By accurately modeling the structure, the software can provide insights into the most efficient use of materials, reducing waste and costs. This feature is particularly valuable in large-scale projects where material optimization can result in significant savings.

Quantity Takeoffs and Cost Estimation

BIM software streamlines the quantity takeoff process, allowing for accurate estimation of material quantities and costs. By extracting information directly from the 3D models, the software can provide precise quantity takeoffs, eliminating the need for manual calculations and reducing human error. This functionality enables more accurate cost projections and better cost control throughout the project.

Collaboration and Communication

BIM software provides a centralized platform for collaboration and communication among project stakeholders. With real-time access to project information, professionals can easily share and exchange data, fostering better coordination and reducing misunderstandings. This collaborative approach enhances overall project efficiency and ensures smooth communication throughout the construction process.

These are just a few of the key features and functionalities of BIM software for structural framing. The advancements in technology have led to increasingly sophisticated software solutions that cater specifically to the needs of professionals in the construction industry. By leveraging these tools, architects, engineers, and construction professionals can enhance their projects and achieve improved outcomes.

Best Practices for Incorporating BIM into Structural Framing Workflows

In order to maximize the benefits of BIM in structural framing, it is essential to incorporate it into existing workflows effectively. Here are some best practices to consider when integrating BIM into your structural framing processes.

Start Early and Involve all Stakeholders

To ensure a seamless integration of BIM into your structural framing workflows, it is crucial to start early in the project lifecycle. By involving all relevant stakeholders from the outset, you can establish clear goals and expectations for the use of BIM. This early collaboration allows for better coordination and ensures that everyone is on the same page.

Invest in Training and Education

BIM software and technology are continuously evolving, so it is essential to invest in training and education for your team. Providing comprehensive training programs and certifications will enable your team members to fully leverage the capabilities of BIM software. This investment in training will not only enhance their skills but also increase their confidence in using BIM effectively.

Standardize Processes and Workflows

To ensure consistency and efficiency, it is essential to standardize processes and workflows when incorporating BIM into structural framing. Establishing clear protocols and guidelines for modeling, clash detection, and collaboration will streamline the workflow and minimize errors or conflicts. Standardization also facilitates better coordination between different trades and ensures that everyone is working towards the same goals.

Foster Collaboration and Communication

BIM is a collaborative tool, so fostering collaboration and communication among project stakeholders is crucial. Encourage regular meetings and discussions to share progress, address issues, and ensure that everyone is aligned with the project objectives. Utilize the collaborative features of BIM software to facilitate real-time sharing of information and enhance communication between team members.

Continuously Evaluate and Improve

Incorporating BIM into your structural framing workflows is an ongoing process. Continuously evaluate the effectiveness of the implementation and seek feedback from your team members. Identify areas for improvement and implement necessary changes to optimize the use of BIM. Regularly updating your workflows and processes based on lessons learned will ensure that you are maximizing the benefits of BIM in your projects.

By following these best practices, you can effectively incorporate BIM into your structural framing workflows and harness its full potential. The seamless integration of BIM will drive efficiency, collaboration, and improved project outcomes, ultimately enhancing your overall construction processes.

Training and Certification Programs for BIM in Structural Framing

To fully leverage the power of BIM in structural framing, it is essential to invest in training and certification programs for your team members. These programs provide the necessary skills and knowledge to effectively utilize BIM software and technology in your projects. Let's explore some of the training and certification programs available for BIM in structural framing.

Autodesk Certified Professional (ACP) - Revit Structure

Autodesk offers the Certified Professional (ACP) program for Revit Structure, one of the leading BIM software solutions for structural framing. This program validates the skills and knowledge necessary to effectively utilize Revit Structure in structural framing projects. The ACP certification demonstrates proficiency in creating 3D models, performing clash detection, and optimizing material usage using Revit Structure.

BuildingSMART Professional Certification

BuildingSMART, an international organization focused on promoting open standards for BIM, offers a professional certification program for BIM. This certification validates the skills and knowledge necessary to effectively implement BIM processes in structural framing projects. BuildingSMART certification demonstrates proficiency in BIM workflows, clash detection, collaboration, and coordination.

Online Courses and Training Programs

Various online platforms offer courses and training programs specifically tailored for BIM in structural framing. These programs provide comprehensive training on BIM software and technology, covering topics such as 3D modeling, clash detection, material optimization, and collaboration. Online courses offer flexibility and convenience, allowing team members to learn at their own pace and apply their knowledge directly to their projects.

In-house Training Programs

In addition to external training and certification programs, you can also develop in-house training programs for your team members. These programs can be customized to suit your specific needs and project requirements. By providing hands-on training and practical exercises, you can ensure that your team members are proficient in using BIM software for structural framing.

Investing in training and certification programs for BIM in structural framing is essential to maximize the benefits of this technology. By equipping your team members with the necessary skills and knowledge, you can enhance their capabilities and improve project outcomes. These training and certification programs provide a solid foundation for incorporating BIM into your structural framing workflows.

Challenges and Obstacles in Adopting BIM for Structural Framing

While BIM offers numerous benefits in enhancing structural framing, there are also challenges and obstacles that organizations may face when adopting this technology. Let's explore some of the common challenges and how they can be overcome.

Cost of Implementation

One of the primary challenges in adopting BIM for structural framing is the initial cost of implementation. BIM software licenses, hardware requirements, and training programs can be expensive, especially for smaller organizations. However, it is important to consider the long-term benefits and cost savings that can be achieved through the use of BIM. By conducting a cost-benefit analysis and demonstrating the return on investment, organizations can justify the initial expenses associated with BIM implementation.

Resistance to Change

Resistance to change is another common challenge in adopting BIM for structural framing. Some team members may be hesitant to embrace new technologies and workflows, fearing the learning curve or potential disruptions to their established processes. Overcoming this resistance requires effective change management strategies, including clear communication, training programs, and involving team members in the decision-making process. By addressing concerns and emphasizing the benefits of BIM, organizations can encourage acceptance and adoption.

Lack of Standardization

The lack of standardization in BIM processes and workflows can pose challenges when adopting BIM for structural framing. Different organizations may have varying approaches to BIM implementation, leading to inconsistencies and difficulties in collaboration. To overcome this challenge, it is essential to establish clear protocols and guidelines for BIM usage. Organizations should also consider adopting industry standards and best practices to ensure compatibility and streamline collaboration.

Data Management and Security

Managing large amounts of data generated by BIM software can be a challenge, especially in complex structural framing projects. Data security and privacy are also crucial considerations. Organizations need to implement robust data management systems and protocols to ensure the integrity, accessibility, and security of project information. This may involve investing in secure cloud-based storage solutions and establishing data governance policies.

Skills Gap

The skills gap is another challenge that organizations may face when adopting BIM for structural framing. BIM requires a specific skill set that may not be readily available within the organization. This challenge can be addressed through training and certification programs, as mentioned earlier. By investing in the development of your team members' skills, you can bridge the skills gap and ensure that your organization is equipped to effectively utilize BIM.

By recognizing and addressing these challenges, organizations can successfully adopt BIM for structural framing and unlock its full potential. With proper planning, training, and change.

Tensor Blogspot